What is RPS?

What is RPS? #mcad #design #rps #mechanical #automobile.

Welcome to our YouTube channel! In this video, we’ll explore an essential aspect of BIW (Body-in-White) fixture design: RPS, which stands for Reference Point System.

Join us as we delve into the significance of RPS and how it ensures precision and accuracy in automotive manufacturing.

In automotive manufacturing, the BIW refers to the stage of production where the car body shell is assembled and welded together before other components are added.

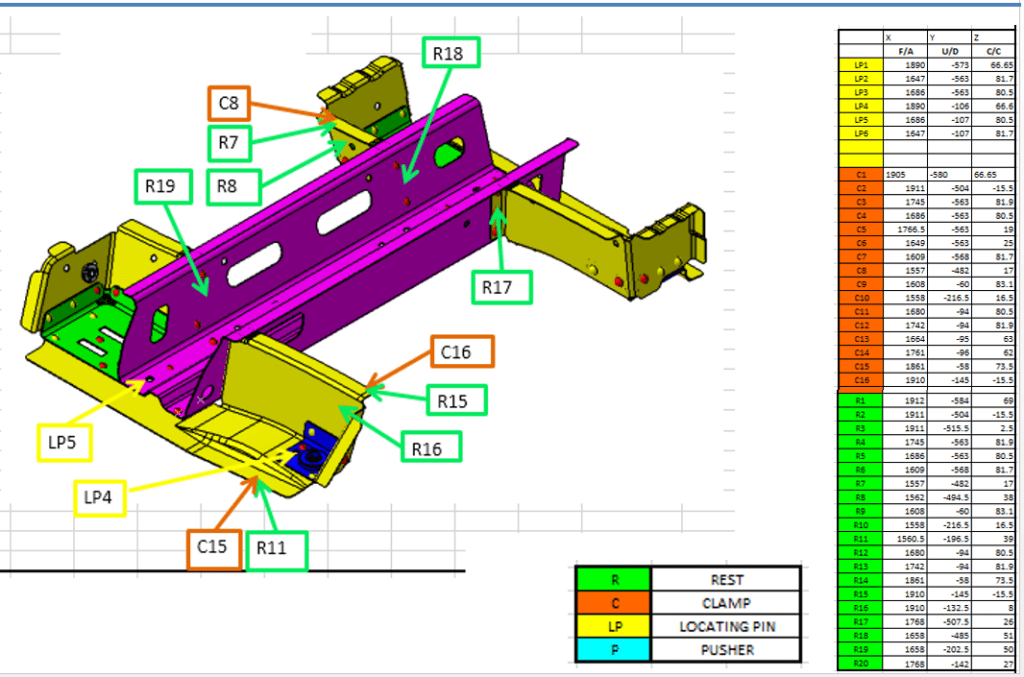

A BIW fixture is a specialized tool or jig used during this stage to hold and position the individual body panels and components accurately for welding.

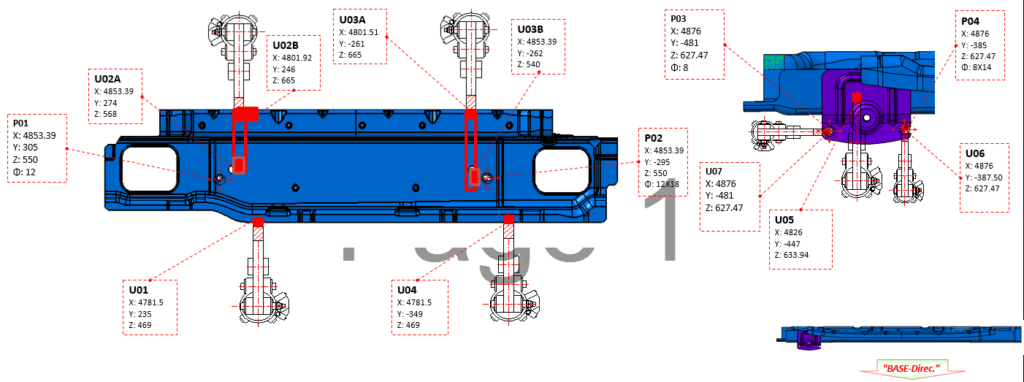

The RPS, or Reference Point System, in BIW fixture design, refers to a set of established points or features on the car body that serve as reference points for aligning and positioning the fixture. These reference points are typically based on specific parts of the car body, such as mounting holes, flanges, or datum surfaces, which are measured and located precisely.

By using the RPS in fixture design, manufacturers ensure that the BIW fixture aligns with the car body accurately and consistently, facilitating proper assembly and welding operations.

The RPS helps maintain dimensional integrity and positional accuracy throughout manufacturing, resulting in high-quality and consistent body assemblies.

Don’t forget to like this video, subscribe to our channel for more informative content, and leave your comments and questions below. Thank you for watching!

Here are some of the benefits of using an RPS in BIW fixture design:

- Improved accuracy: The RPS helps to ensure that the BIW parts are correctly aligned and positioned in the fixture, which is essential for accurate welding and assembly.

- Reduced rework: By ensuring that the BIW parts are correctly aligned and positioned in the fixture, the RPS helps to reduce the risk of rework and scrap.

- Increased efficiency: The RPS helps to facilitate the design and manufacturing of the fixture, as it provides a standard reference system for all of the fixture components.

To design an RPS for a BIW fixture, the following steps are typically followed:

- Identify the key features of the BIW parts that will be used as reference points.

- Determine the location of the reference points on the BIW parts.

- Create a coordinate system for the RPS.

- Define the relationship between the RPS and the BIW parts.

- Document the RPS and distribute it to all stakeholders involved in the fixture design and manufacturing process.

The RPS is an essential tool for designing accurate and efficient BIW fixtures. By using an RPS, fixture designers can ensure that the BIW parts are correctly aligned and positioned in the fixture, which leads to improved accuracy, reduced rework, and increased efficiency.