What is RISER in BIW Fixture Design?

Are you familiar with the term RISER in BIW fixture design? If not, get ready to expand your knowledge and enhance your understanding of this innovative concept. In the world of automobile manufacturing, Body-in-White (BIW) fixtures play a crucial role in ensuring precision and accuracy during assembly. And within this realm, RISER stands as a game-changer that promises to revolutionize BIW fixture design. So, buckle up and join us on this exciting journey as we delve into the intricacies of RISER and how it is reshaping the future of automotive production.

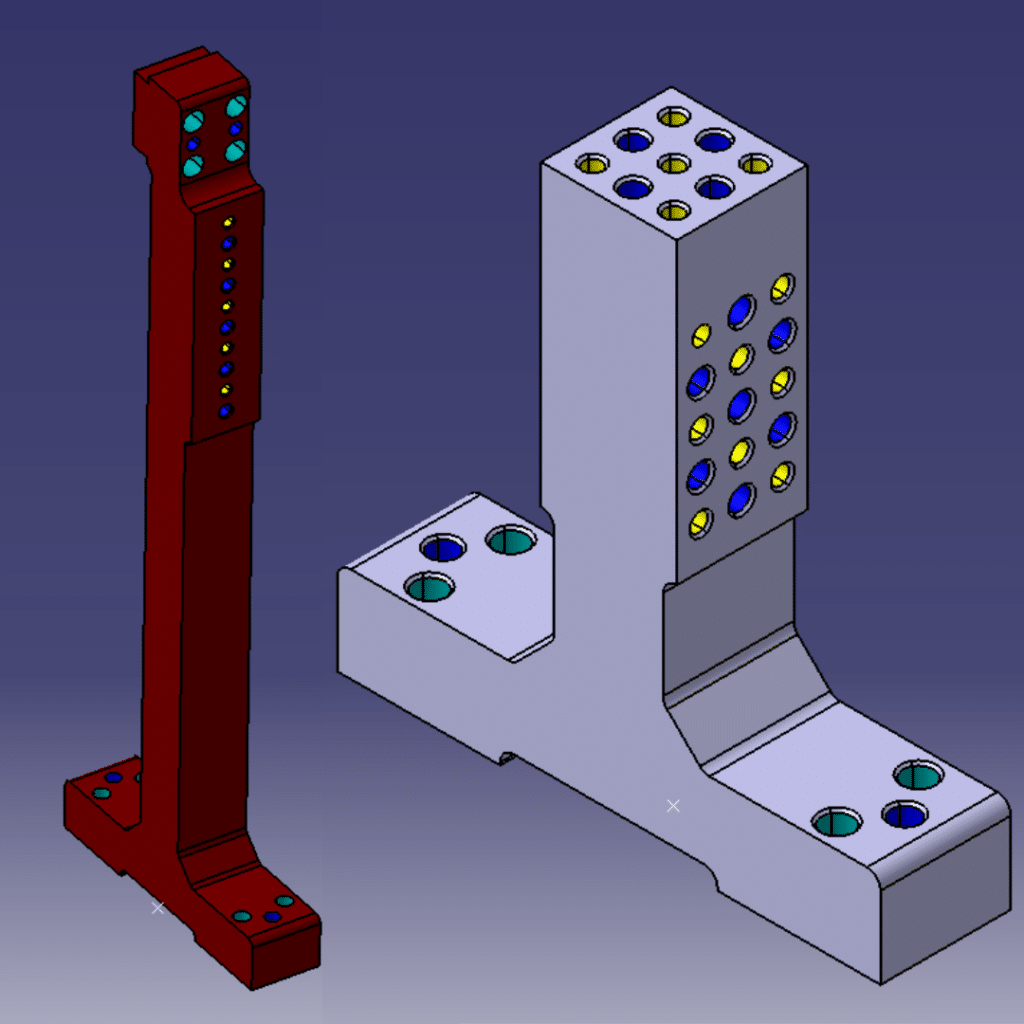

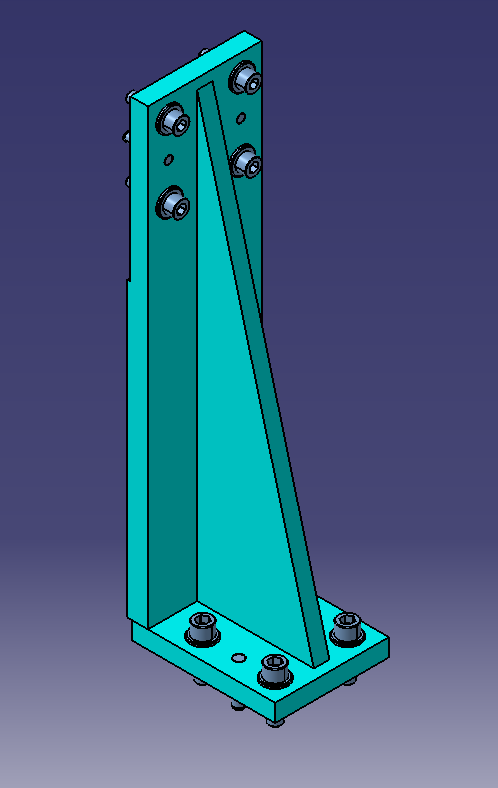

A riser in BIW fixture design is a component that is used to raise the height of a clamp or pin cylinder. It is typically mounted on the base plate of the fixture and is made of steel or aluminum. Risers can be of various shapes and sizes, typically L-shaped or T-shaped.

Risers are used for a variety of reasons in BIW fixture design. One common reason is to provide clearance for other components in the fixture. For example, a riser may be used to raise the height of a clamp cylinder so that it does not interfere with a welding torch.

Another common reason to use a riser is to support a large or heavy part. For example, a riser may be used to raise the height of a clamp cylinder to support a large body panel.

Risers are also used to adjust the position of a clamp or pin cylinder. For example, a riser may move the clamp cylinder closer to or further away from the assembled part.

When designing a BIW fixture, it is essential to consider the placement of risers carefully. Risers should be placed to provide the necessary support and clearance without interfering with the assembly process.

Here are some of the benefits of using risers in BIW fixture design:

- Increased clearance for other components in the fixture

- Improved support for large or heavy parts

- Ability to adjust the position of clamp or pin cylinders

- Increased flexibility in fixture design

Risers are an essential component of BIW fixture design and can help improve the assembly process’s quality and efficiency.

Gas-cut risers are made by cutting steel plates up to 50mm or 63mm thick using a gas-cutting process. They are typically used in BIW fixtures for supporting heavy loads, such as clamps and actuators. Gas-cut risers are strong and durable, but they can be more expensive to manufacture than other types of risers.

Weldment risers are made by welding together two or more pieces of steel plate or tubing. They are typically used in BIW fixtures for supporting lighter loads, such as locators and guides. Weldment risers are less expensive to manufacture than gas-cut risers, but they may not be as strong or durable.

In this training video, you’ll learn how to use BIW fixtures to design riser systems. You’ll learn how to set up the fixtures, use the software to create the sketches and weld the risers.

If you want to learn how to design risers for your next job, this training video is for you! By the end of this video, you’ll have the skills you need to start designing riser systems for your clients.

Don’t miss out on this exclusive training opportunity – register now to learn how to use BIW fixtures to design riser systems! BIW Fixture Design Interview Series: Riser #design #mcad #mechanical #riser #training #biwfixture In this new episode of the BIW Fixture Design Interview Series, we discuss risers used in fixture design.

If you are interested in a career in BIW fixture design, then be sure to check out this episode of the BIW Fixture Design Interview Series. To know more, Contact us at 9096708490 or visit our website www.mcadsolution.com

In conclusion, RISER is a crucial component in BIW fixture design that helps ensure accuracy and precision during the assembly process. By using RISER, manufacturers can effectively manage the dimensional variations of body-in-white components, reducing rework and ensuring consistent quality. This innovative technology offers numerous benefits, including improved productivity, reduced costs, and enhanced overall efficiency. As the automotive industry continues to evolve and demand higher standards of quality and efficiency, it is imperative for manufacturers to embrace advanced technologies like RISER to stay competitive in the market. By incorporating RISER into BIW fixture design processes, manufacturers can achieve optimal results and deliver high-quality vehicles to customers.