What is BIW?

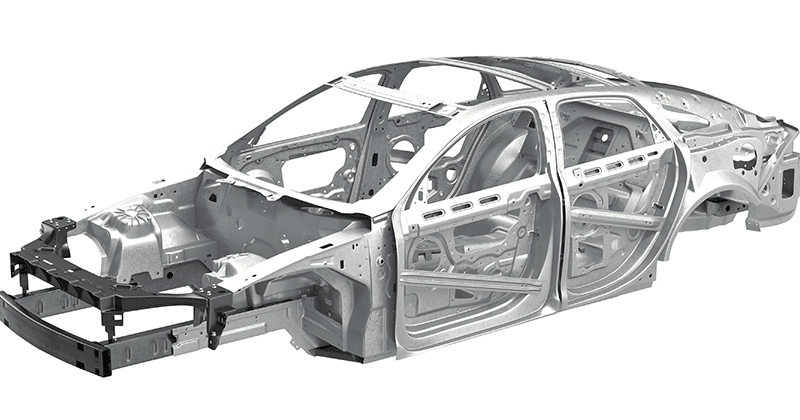

BIW stands for Body in White. It is the stage in automobile manufacturing in which the vehicle body sheet metal has been assembled, but before the vehicle, chassis sub-assemblies, or trims (glass, door locks/handles, seats, electronics parts, etc.) have been integrated into the structure.

The BIW is the main load-bearing structure of the vehicle, and it is responsible for protecting the occupants in the event of a collision. It is also vital for the BIW to be lightweight and aerodynamic to improve fuel efficiency and handling.

BIWs are typically made from high-strength steel, but other materials, such as aluminium and carbon fibre, are also increasingly used. The BIW is assembled using various techniques, including welding, riveting, and bonding.

Once the BIW is complete, it is painted, and the other vehicle components are added.

Here are some of the critical functions of the BIW:

- Provides structural support for the vehicle

- Protects the passenger in the occasion of a collision

- Improves fuel efficiency and handling

- Provides a mounting point for the other components of the vehicle

BIW design and manufacturing is a complex process, one of the most important aspects of automobile manufacturing.

#BIW: A Beginner's Guide. #BIW #fixturedesign #manufacturing #engineering #automotive #design.

BIW stands for Body in White. It is the stage in automobile manufacturing in which a car body’s frame has been joined together, i.e., before painting and before motor, chassis sub-assemblies, or trim have been integrated into the structure.

Assembly involves various techniques: welding- spot and MIG MAG or friction, stir, riveting, clinching, bonding&laser brazing. The term “body in white” is thought to have originated from the practice of painting car bodies white before they were fitted with the final trim.

This was done to protect the metal from corrosion & to make any defects in the finish more visible. BIW is a critical stage in the manufacturing process, as it determines the overall shape & structure of the car. The exactness of the BIW body is crucial for ensuring that the automobile vehicle is safe & serves as designed. In recent years, there has been a trend toward light-weighting of BIWs.

This is being done to improve fuel efficiency and reduce emissions. Some ways BIWs are being made lighter include high-strength steels, aluminum &composite materials. BIW fixture design is the process of designing &manufacturing fixtures that are used to hold &locate car body components during welding, assembly &other manufacturing operations. Fixtures are essential for assuring that car bodies are assembled accurately & consistently & they can also support to enhance productivity and quality.

I hope this helps! For more valuable information, like and subscribe to our channel. I hope this helps!