What is Slinding Unit in BIW Fixture Design?

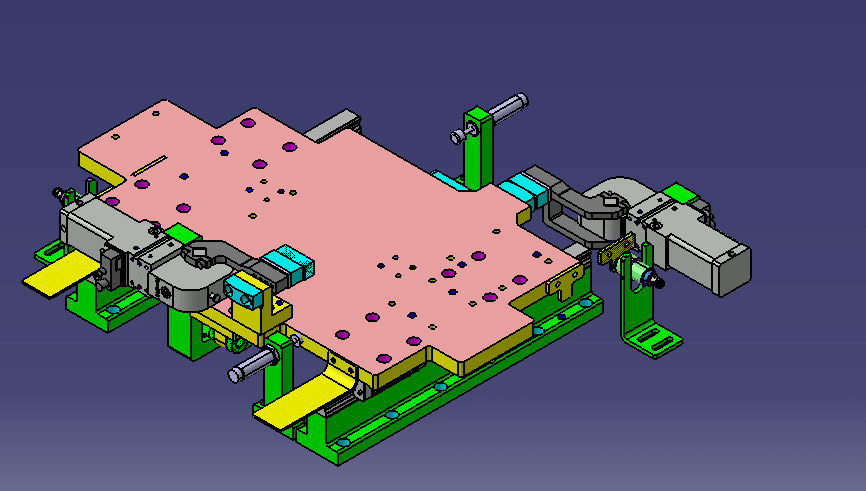

A slide unit is a positioning unit that is used to position fixtures, weld guns, units, or robots into position for further operations. It is a common component of body-in-white (BIW) welding fixtures, which are used to hold and position car body parts together during welding.

Slide units typically consist of the following components:

- Slide block: A rectangular block that moves along a guide rail.

- Guide rail: A hardened steel rail that provides a precise and smooth surface for the slide block to move along.

- Linear cylinder: A pneumatic or hydraulic cylinder that is used to drive the slide block along the guide rail.

- End stops: Two stops that prevent the slide block from moving too far in either direction.

- Sensors: Two sensors that are used to detect the position of the slide block.

Slide units are used in BIW welding fixtures for a variety of purposes, including:

- To position car body parts in the correct location for welding.

- To move car body parts into and out of the welding area.

- To position weld guns in the correct location relative to the car body parts.

- To position robots in the correct location to perform welding operations.

Slide units are a critical component of BIW welding fixtures, as they help to ensure that car body parts are welded together accurately and precisely.

Here are some of the benefits of using slide units in BIW fixture design:

- Accuracy and precision: Slide units provide a very accurate and precise way to position car body parts and weld guns. This is important for ensuring that welds are strong and consistent.

Sliding units are used in BiW fixtures to allow for precision adjustment. These units can be easily moved along their designated axes, enabling the fine-tuning of the fixture’s position. This is crucial for ensuring that the vehicle components align correctly, as even the slightest misalignment can lead to issues in the final product. - Flexibility: Slide units can be used to create a variety of different fixture designs. This makes them a versatile and flexible solution for a wide range of welding applications.

Another advantage of sliding units is their flexibility. They can be adapted to various fixture designs and vehicle models. This adaptability is invaluable in an industry that constantly evolves with new vehicle designs and production techniques. BiW fixture designers can save time and resources by reconfiguring existing fixtures rather than creating entirely new ones. - Durability: Slide units are typically made from durable materials, such as hardened steel, which makes them able to withstand the harsh conditions of a welding environment.

- Efficiency: Efficiency is a key driver in automotive manufacturing. Sliding units allow for rapid adjustment and repositioning of fixtures, reducing downtime and increasing productivity. As a result, the assembly line can maintain a steady pace, leading to a higher output of vehicles.

Here are some of the factors to consider when designing a slide unit for a BIW welding fixture:

- Load capacity: The slide unit must be able to support the weight of the car body part or weld gun that it will be positioning.

- Accuracy and precision: The slide unit must be able to position the car body part or weld gun with the required accuracy and precision.

- Speed: The slide unit must be able to position the car body part or weld gun at the required speed.

- Durability: The slide unit must be able to withstand the harsh conditions of a welding environment.

Overall, slide units are a versatile and effective way to position car body parts and weld guns in BIW welding fixtures. They provide a high degree of accuracy, precision, and flexibility, making them a valuable tool for welding engineers.

Best Practices in Sliding Unit Integration

To make the most of sliding units in BiW fixture design, consider the following best practices:

1. Collaborate with Fixture Design Experts

Working with experienced fixture designers who understand the nuances of automotive manufacturing is essential. They can help you determine the most suitable sliding unit configurations for your specific needs.

2. Regular Maintenance

Sliding units must be well-maintained to function optimally. Implement a regular maintenance schedule to ensure that they continue to perform accurately.

3. Training

Proper training of assembly line personnel is vital. They should be well-versed in using sliding units and fixtures to ensure the precise assembly of vehicle components.

Conclusion

In the world of automotive manufacturing, precision and efficiency are non-negotiable. Sliding units in BIW fixture design contribute significantly to both. They allow for precise adjustments, enhance flexibility, improve efficiency, and create a safer working environment. By embracing the power of sliding units, automotive manufacturers can achieve higher quality and increased productivity in their BiW assembly processes.

The importance of sliding units in BiW fixture design cannot be overstated. They are the silent heroes that enable the creation of top-quality vehicles. So, the next time you admire the flawless lines and perfect fit of an automobile, you can appreciate the role sliding units play in making it possible.

Slide units are a versatile and essential component for BIW welding fixtures. They provide a high degree of accuracy, precision, and flexibility, making them a valuable tool for welding engineers.

Additional Tips for Designing and Using Slide Units in BIW Welding Fixtures

Here are a few additional tips for designing and using slide units in BIW welding fixtures:

- Use high-quality materials and components to ensure durability and long service life.

- Design the slide unit for the specific load capacity and accuracy and precision requirements of the application.

- Use linear guides and bearings to ensure smooth and precise movement.

- Use end stops to prevent the slide block from moving too far in either direction.

- Use sensors to detect the position of the slide block and provide feedback to the control system.

- Install and maintain the slide unit properly to ensure optimal performance and safety.

By following these tips, you can design and use slide units to create effective and reliable BIW welding fixtures.