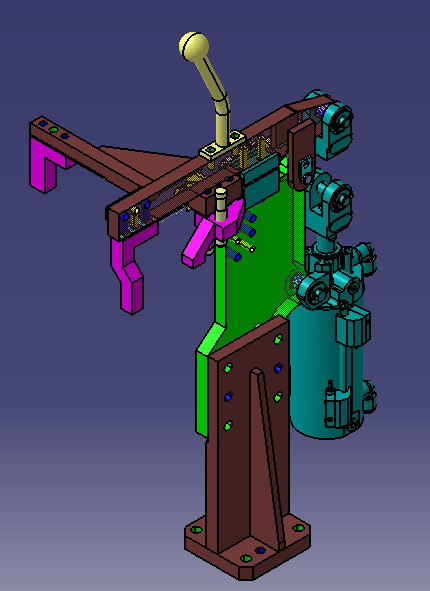

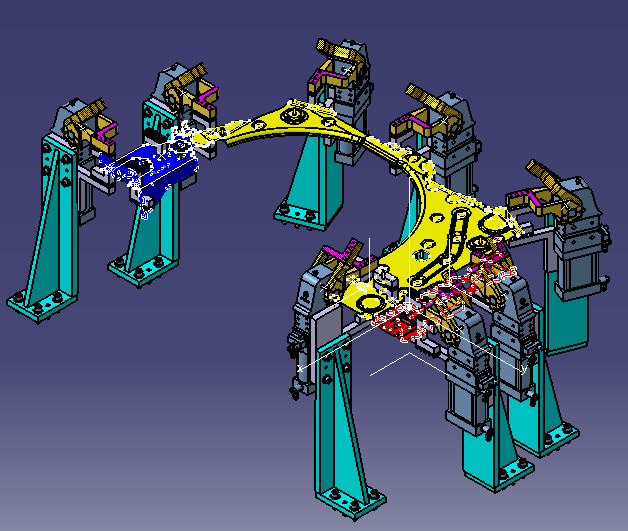

Clamp units are a main unit of body-in-white (BIW) fixture design. Clamps units are mainly used to hold Car body parts for welding and different machining operations. Clamp units must be able to provide a high degree of accuracy and precision, as well as the necessary clamping force to hold the car body parts in place during the welding process.

There are a variety of different clamp unit designs that can be used in BIW fixture design. The specific design of the clamp unit will depend on the specific car body part being welded and the requirements of the welding process.

Some common parts used in clamp units for BIW fixture design include:

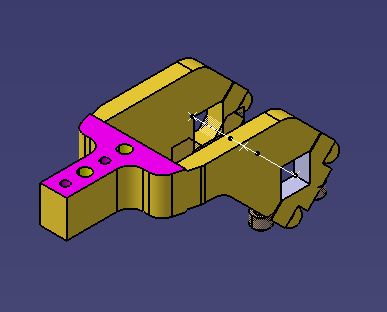

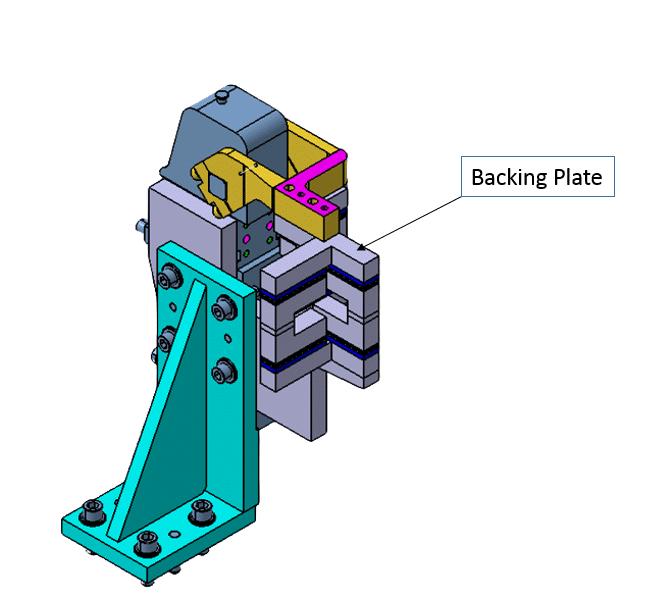

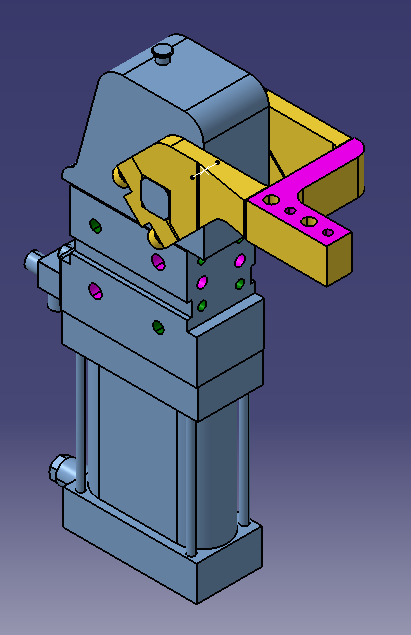

- A clamp arm: The clamp arm is the part of the clamp unit that applies the clamping force to the car body part.

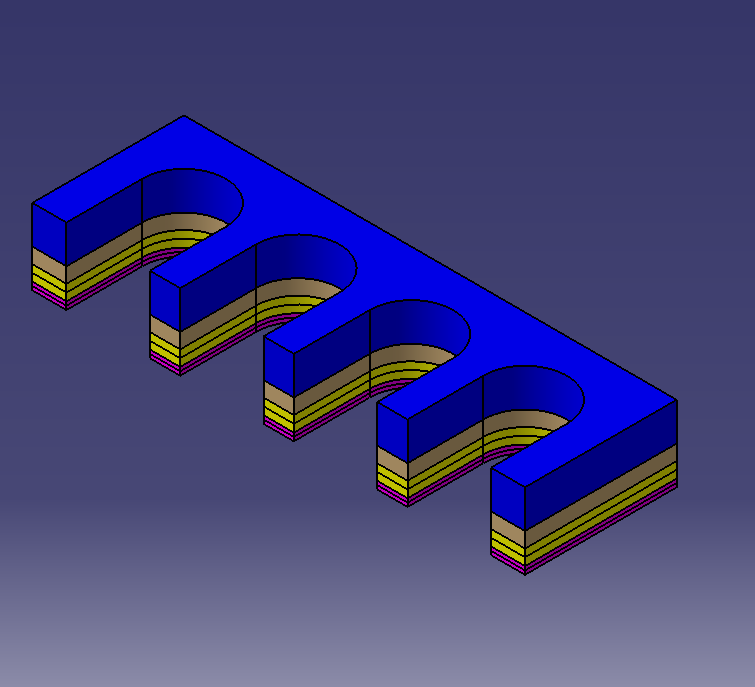

- A clamp finger/ Mylar / NC Block: The clamp finger/ Mylar / NC Block is the part of the clamp unit that contacts the car body part.

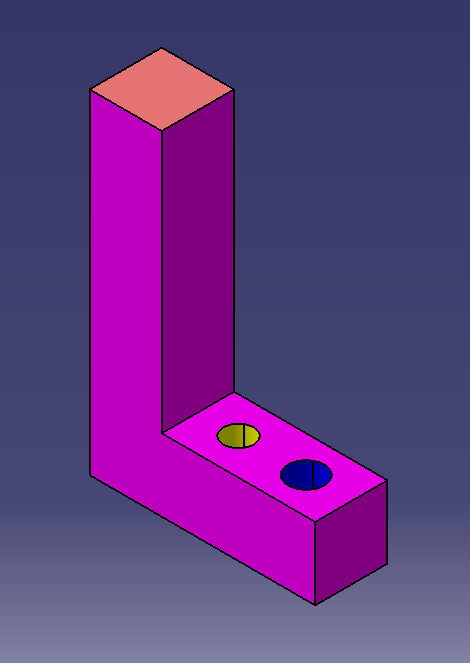

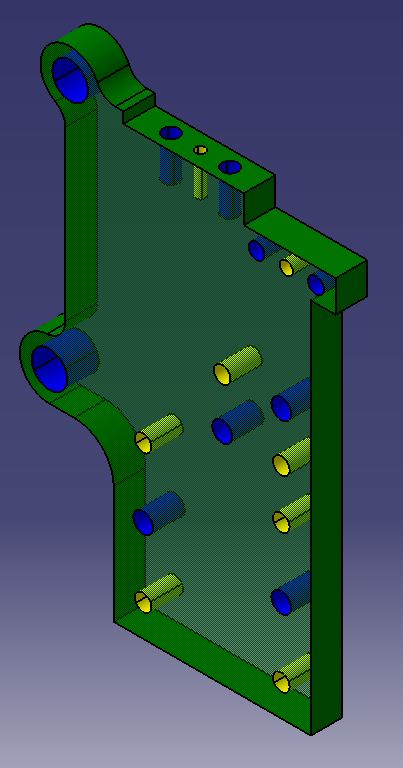

- A backing plate: The backing plate is the part of the clamp unit that provides support for the clamp arm and clamp finger.

- A clamping cylinder: The clamping cylinder is the part of the clamp unit that provides the power to apply the clamping force.

- Dolly Plate / Blade : Dolly Plate / Blade is the part of clamp unit which supports cylinder, rest mylar, other parts of unit and its mounted on Riser.

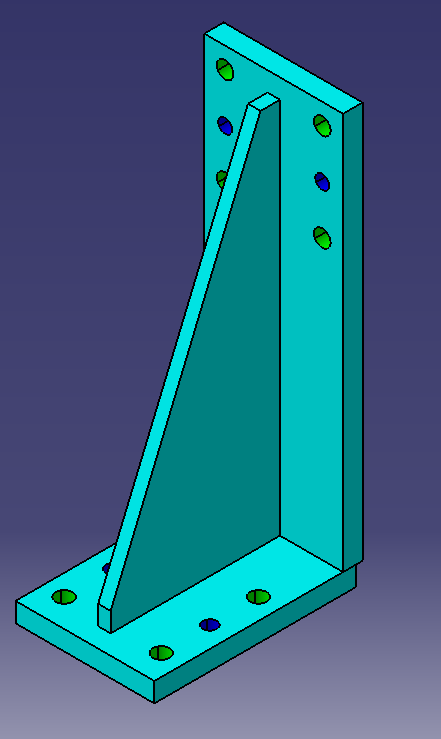

- Riser : Riser is a weldment or gascut part which proives the strength and height to the clamp unit and its mounted on Base unit.

- Shim : Shim is the part or assembly used for mainly adjustment purposes.

Here are some of the benefits of using clamp units in BIW fixture design:

- Accuracy and precision: Clamp units provide a very accurate and precise way to hold and position car body parts / panels in the correct position for welding applications. This is important for ensuring that welds are strong and consistent.

- Flexibility: Clamp units can be designed to hold and position a variety of different car body parts. This makes them a versatile solution for a wide range of welding applications.

- Durability: Clamp units are typically made from durable materials, such as steel and hardened steel. This makes them able to withstand the harsh conditions of a welding environment.

However, there are also some drawbacks to using clamp units in BIW fixture design:

- Cost: Clamp units can be more expensive than other types of positioning units, such as rough units and pin units.

- Complexity: Clamp units are more complex to design and manufacture than other types of positioning units.

- Maintenance requirements: Clamp units require regular maintenance to ensure optimal performance and safety.

Overall, clamp units are a valuable tool for BIW fixture designers. They provide a number of advantages over other types of positioning units, such as accuracy, precision, and flexibility. However, they are also more expensive and complex than other types of positioning units.

Here are some examples of applications where clamp units are commonly used in BIW fixture design:

- Welding car body panels: Clamp units are used to hold and position car body panels in the correct location for welding. This includes panels such as the roof, doors, hood, and trunk.

- Welding structural members: Clamp units are also used to hold and position structural members in the correct location for welding. This includes members such as the frame rails, cross members, and A-pillars.

- Welding subassemblies: Clamp units can also be used to hold and position subassemblies in the correct location for welding. This includes subassemblies such as the front end module and rear end module.

Clamp units are an essential component of BIW fixture design. By understanding the benefits and drawbacks of clamp units, fixture designers can select the right positioning unit for the job.

Conclusion

n the complex world of automotive manufacturing, clamp units in BiW fixture design are the unsung heroes. They securely hold and precisely position components, ensuring that vehicles are assembled with accuracy and efficiency. Their role in BiW fixture design is indispensable, as they are essential in achieving high-quality vehicle assembly, streamlining production processes, and improving worker well-being.

The next time you admire the smooth lines and perfect assembly of an automobile, remember that clamp units are the silent champions behind the scenes, making it all possible. They are the key to a well-orchestrated manufacturing process, ensuring that each vehicle that rolls off the assembly line meets the highest standards of quality and performance.

Additional Tips for Designing and Using Slide Units in BIW Welding Fixtures

Here are a few additional tips for designing and using slide units in BIW welding fixtures:

- Use high-quality materials and components to ensure durability and long service life.

- Design the slide unit for the specific load capacity and accuracy and precision requirements of the application.

- Use linear guides and bearings to ensure smooth and precise movement.

- Use end stops to prevent the slide block from moving too far in either direction.

- Use sensors to detect the position of the slide block and provide feedback to the control system.

- Install and maintain the slide unit properly to ensure optimal performance and safety.

By following these tips, you can design and use slide units to create effective and reliable BIW welding fixtures.